CyclAFlor® Applications

Explore CyclAFlor Coatings for Additive Manufacturing

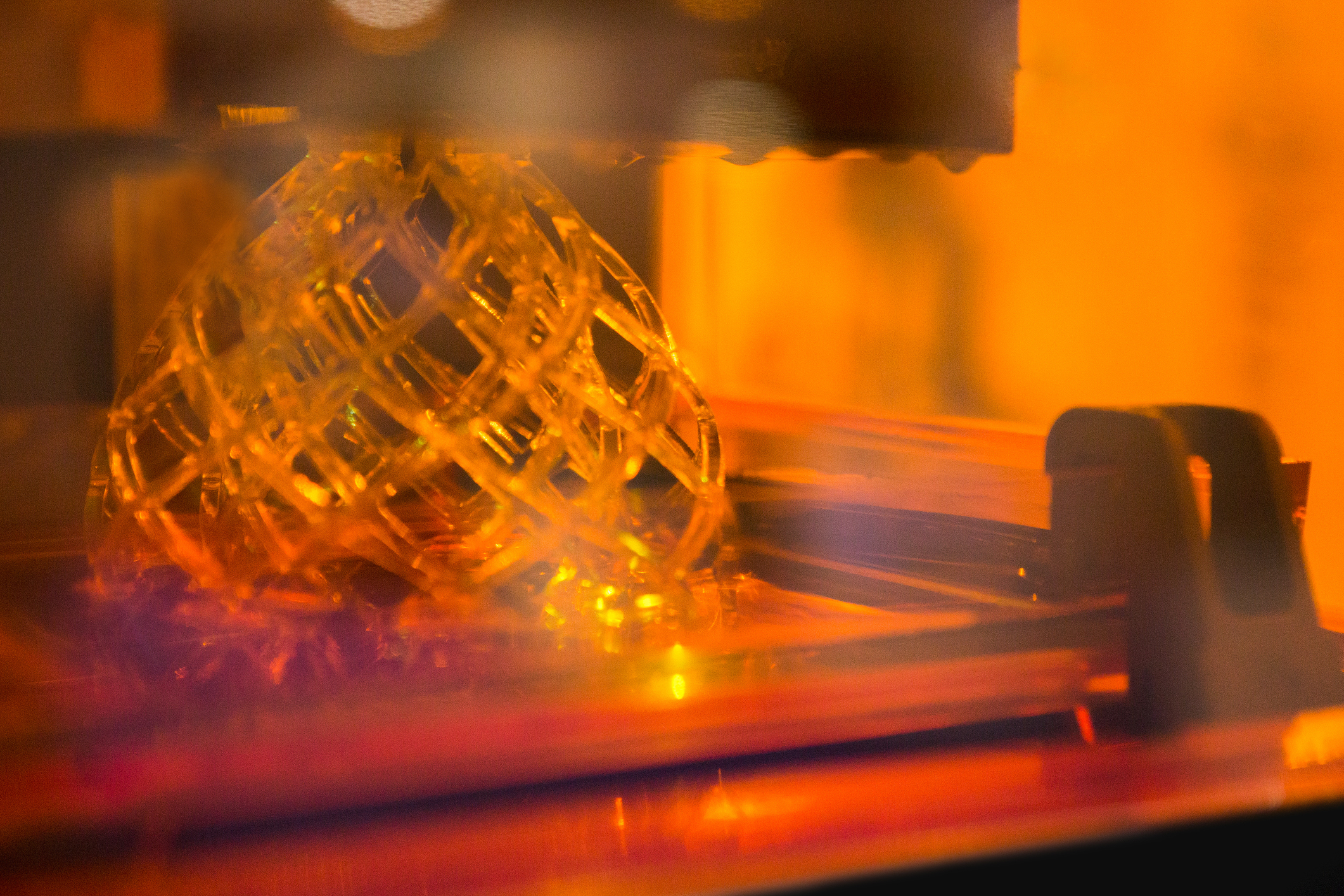

CyclAFlor® Shield offers unique advantages in additive manufacturing, particularly as protective coatings in stereolithographic 3D printing. These properties make them indispensable for enhancing performance and extending the lifespan of key components. Key benefits include:

Chemically Inert

CyclAFlor Shield is chemically inert, ensuring it will not react with photopolymer resins, maintaining the integrity of the printing process.

Extremely Low Surface Energy

The low surface energy of CyclAFlor Shield eliminates peel forces, facilitating smoother printing and reducing the risk of defects.

UV Transparency

UV transparency ensures that CyclAFlor Shield does not interfere with photopolymerization, allowing for precise and efficient curing of resins.

Crack and Scratch Resistance

CyclAFlor Shield resists cracks and scratches, significantly extending the life of resin trays and reducing maintenance costs.

High Solubility

Its high solubility in perfluorinated solvents like CyclaSolv® makes CyclAFlor Shield easy to apply using standard dip or spin coating techniques, ensuring a uniform and durable coating.

Enhance Your Additive Manufacturing Process

CyclAFlor amorphous fluoropolymers are revolutionizing additive manufacturing by providing robust, reliable, and easy-to-apply coatings. These coatings not only improve the performance and durability of stereolithographic 3D printer resin trays but also streamline the manufacturing process, ensuring high-quality prints every time.

Contact us today to discover how CyclAFlor coatings can elevate your addition manufacturing operations.