Part 2 of a Two-Part Series on Optical Interposers and the Waveguide Materials That Enable Them

From Concept to Construction

In Part 1, we compared copper interconnects between computer chips to crowded highways while thinking of optical interposers as high-speed rail lines. But even the best rail system is only as good as the tracks it runs on. In an optical interposer, those tracks are waveguides — microscopic channels that confine and guide light between chips.

Waveguides may be invisible to the naked eye, but they are the make-or-break component of the entire optical interposer concept. They are the channels that carry digital signals — except instead of electrons, they guide photons. The material used to build them determines how efficiently light travels and how much data can move without loss, as well as the scalability and economics of the system.

What Makes a Good Waveguide?

An effective waveguide material must:

- Confine light efficiently with the right refractive index contrast.

- Be transparent with low propagation loss across telecom wavelengths.

- Couple well to standard optical fibers.

- Survive the thermal and mechanical stresses of semiconductor packaging.

- Be fabrication-friendly at wafer scale.

These requirements form a checklist against which to evaluate conventional and emerging materials.

Conventional Material Platforms

Much optical interposer research today focuses on familiar materials used in silicon photonics:

- Silicon (SiO2): Offers high index contrast and compact device designs; limitations include thermal conductivity and difficulty coupling to external optical fiber.

- Silicon Nitride (Si3N4): Delivers ultra-low propagation loss (<0.1 dB/cm) and broad transparency, but presents challenges with signal responsiveness, power consumption, and processing cost and complexity.

- Silicon Oxynitride (SiON): Provides a tunable refractive index as a middle ground between silicon and silicon nitride to enable flexible device design, and is compatible with standard manufacturing processes, but can suffer from absorption losses unless carefully treated.

- Glass: Excellent optical transparency and manufacturability but can be difficult to create compact circuits and integrate with other system components.

Each of these materials has strengths — and limitations. That’s why the search for new options is ongoing.

Amorphous Fluoropolymers (AFPs): CYTOP® and Teflon AF™

Amorphous fluoropolymers such as CYTOP (Asahi Glass) and Teflon AF (Chemours) have been studied since the 1990s for integrated optics but they’ve been largely overlooked in the context of optical interposers.

Key Properties

Research has shown that these fluoropolymers share several attractive traits:

- Low refractive index (1.29–1.34) — Close to glass optical fibers, reducing coupling loss (Yang et al., 2008).

- Broad transparency — From UV (~200 nm) to mid-IR (~3 µm), covering telecom bands (Yang et al., 2008).

- Low scattering and birefringence — Thanks to their amorphous molecular structure (Hanada et al., 2010).

- Proven processing methods — Spin coating, embossing, femtosecond laser writing, and plasma etching (Hanada et al., 2010; Melin et al., 2005).

- Compatibility with silicon systems — Demonstrated in microfluidics and biophotonics integration (Leosson & Agnarsson, 2012; Chiu et al., 2010).

Performance Evidence

- CYTOP waveguides have been shown with propagation losses of 0.49–0.91 dB/cm in the visible range (Hanada et al., 2010).

- Teflon AF films provide stable low-index claddings for silicon-based optical devices (Yang et al., 2008; Cho et al., 2009).

- Teflon AF films have been directly patterned with electron-beam lithography to form visible waveguides with sub-micron resolution, demonstrating both index tunability and integration potential (Karre, 2009).

CyclAFlor® Next-Generation AFPs

Building on these foundations, newer amorphous fluoropolymers such as CyclAFlor are being developed with packaging applications in mind. Unlike CYTOP and Teflon AF, which were designed for broad optical use cases, CyclAFlor polymers can be tailored for advanced interconnects. They aim to deliver improved thermal stability, film robustness, and processing flexibility — qualities critical for manufacturable optical interposers — while retaining the low refractive index and transparency of legacy AFPs.

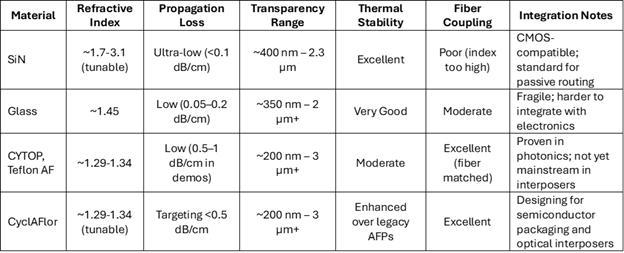

Comparison of Waveguide Materials

While silicon nitride and glass remain standards, amorphous fluoropolymers like CYTOP and Teflon AF offer excellent coupling of optical interposers to external fiber links. CyclAFlor seeks to advance this class of materials with bespoke compositions optimized for semiconductor packaging integration.

Where AFPs Could Fit in Optical Interposers

While silicon and SiN dominate for dense routing, fluoropolymers could excel in transition regions:

- Fiber-to-chip coupling — Their low index makes them excellent candidates for mode-matching layers between interposer waveguides and standard SMF-28 glass optical fibers.

- Cladding materials — Providing low-loss confinement for higher-index cores.

- Embedded polymer waveguides — For low-loss, large-mode-area routing inside glass or silicon substrates.

In other words, they may not replace silicon or SiN — but they could complement them, solving persistent problems in coupling and loss management.

Challenges and Open Questions

The research also highlights hurdles:

- Adhesion issues to substrates (mitigated with silane coupling agents or adhesion layers).

- Thermal stability, since polymers can soften or degrade at high temperatures.

- Patterning precision, where etch processes and embossing methods must be optimized.

These are not trivial challenges, but they are solvable — and the lessons from early biosensing and microfluidics research provide a roadmap for improving integration into interposers.

Looking Ahead

The success of optical interposers may depend as much on materials innovation as on architecture. Silicon nitride and glass are leading now, but their limitations open the door for alternatives. Amorphous fluoropolymers are not untested newcomers. Their use in photonics stretches back over two decades, from biosensing and microfluidics to silicon-integrated optics. These early studies validated their optical pedigree — ultra-low refractive indices, broadband transparency, and processability in waveguide formats.

For now, the opportunity is clear — by extending the reach of photons inside the package, optical interposers promise to reshape the balance between electronics and photonics. And with their unique optical properties, amorphous fluoropolymers remain strong candidates to play a role in that transformation. If they can be adapted to the reliability and integration demands of semiconductor manufacturing, they may evolve from niche research materials into practical building blocks for interposer waveguides and couplers.

References

Hanada, Y., Sugioka, K., & Midorikawa, K. (2010). UV waveguides light fabricated in fluoropolymer CYTOP by femtosecond laser direct writing. Optics Express, 18(2), 446–450. https://doi.org/10.1364/OE.18.000446

Leosson, K., & Agnarsson, B. (2012). Integrated biophotonics with CYTOP. Micromachines, 3(1), 114–125. https://doi.org/10.3390/mi3010114

Chiu, C., Lisicka-Skrzek, E., Tait, R. N., & Berini, P. (2010). Fabrication of surface plasmon waveguides and devices in Cytop with integrated microfluidic channels. Journal of Vacuum Science & Technology B, 28(4), 729–735. https://doi.org/10.1116/1.3449187

Chiu, C., Lisicka-Skrzek, E., Tait, R. N., & Berini, P. (2011). Surface plasmon waveguide devices with Tg-bonded Cytop claddings. Journal of Vacuum Science & Technology B, 29(6), 062601. https://doi.org/10.1116/1.3660801

Melin, J., Hedsten, K., Magnusson, A., Karlén, D., Rödjegård, H., Persson, K., Bengtsson, J., Enoksson, P., & Nikolajeff, F. (2005). Microreplication in a silicon processing compatible polymer material. Journal of Micromechanics and Microengineering, 15(7), S116–S121. https://doi.org/10.1088/0960-1317/15/7/017

Cho, S. H., Godin, J., & Lo, Y.-H. (2009). Optofluidic waveguides in Teflon AF–coated PDMS microfluidic channels. IEEE Photonics Technology Letters, 21(15), 1057–1059. https://doi.org/10.1109/LPT.2009.2022276

Yang, M. K., French, R. H., & Tokarsky, E. W. (2008). Optical properties of Teflon® AF amorphous fluoropolymers. Journal of Micro/Nanolithography, MEMS, and MOEMS, 7(3), 033010. https://doi.org/10.1117/1.2965541

Karre, S. (2009). Direct electron-beam patterning of Teflon-AF and its application to optical waveguiding (Master’s thesis, University of Kentucky). University of Kentucky UKnowledge. https://uknowledge.uky.edu/gradschool_theses/634

Koike, Y., Asai, M., & Yamazato, T. (2011). Progress in low-loss and high-bandwidth plastic optical fibers and their application to short-reach networks. Journal of Polymer Science Part B: Polymer Physics, 49(12), 818–831. https://doi.org/10.1002/polb.22170

Frequently Asked Questions (FAQs)

What makes fluoropolymers attractive for optical interposers?

They have a refractive index close to optical fibers, which reduces coupling loss, and they are transparent across telecom bands (Yang et al., 2008).

Have CYTOP and Teflon AF been used in photonics before?

Yes. Studies since the 1990s demonstrated their use in waveguides, claddings, and biosensing (Hanada et al., 2010; Leosson & Agnarsson, 2012).

What is CyclAFlor and how is it different?

CyclAFlor is a family of next-generation amorphous fluoropolymers that seeks to improve on legacy AFPs with customizable properties optimized for specific applications.

Will fluoropolymers replace silicon nitride or glass?

Unlikely. They are better viewed as complementary — filling roles where fiber coupling and low index are critical.